.

Last Updated 02/11/2023

October 2022 - June 2023

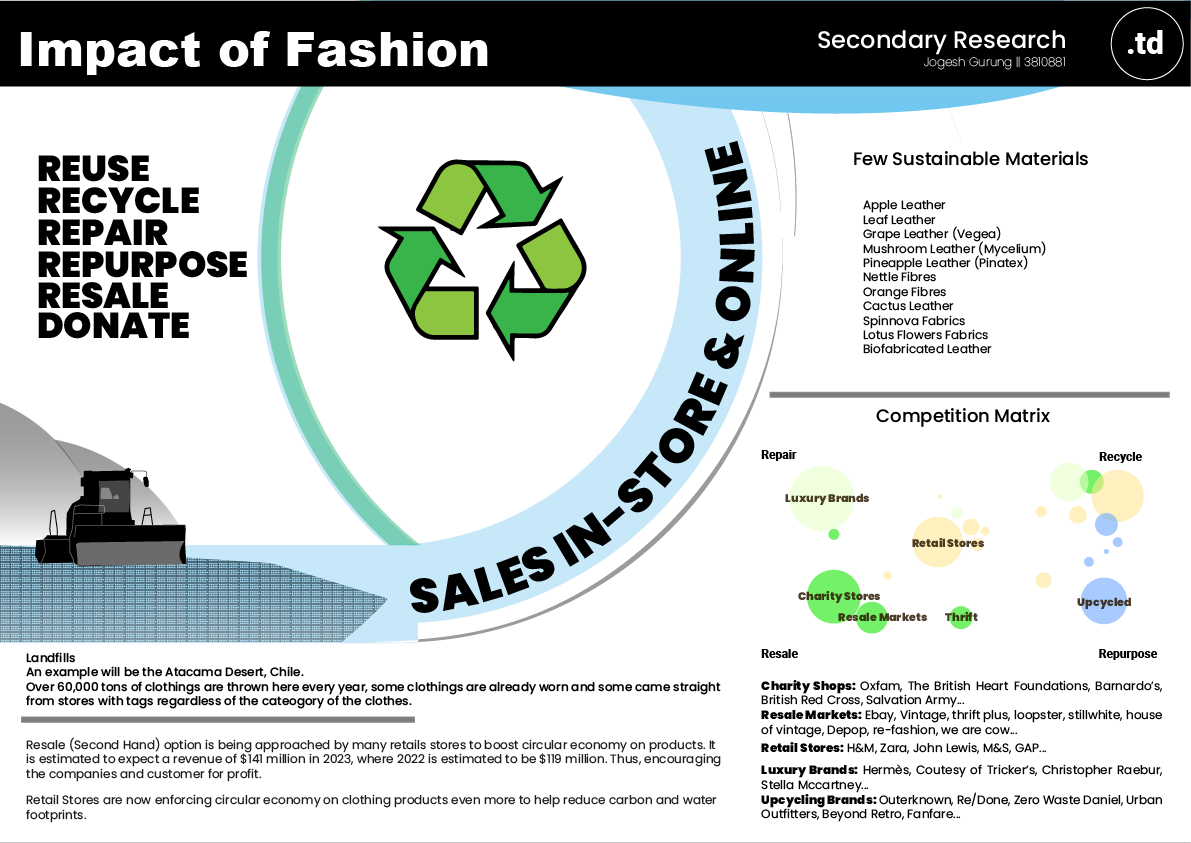

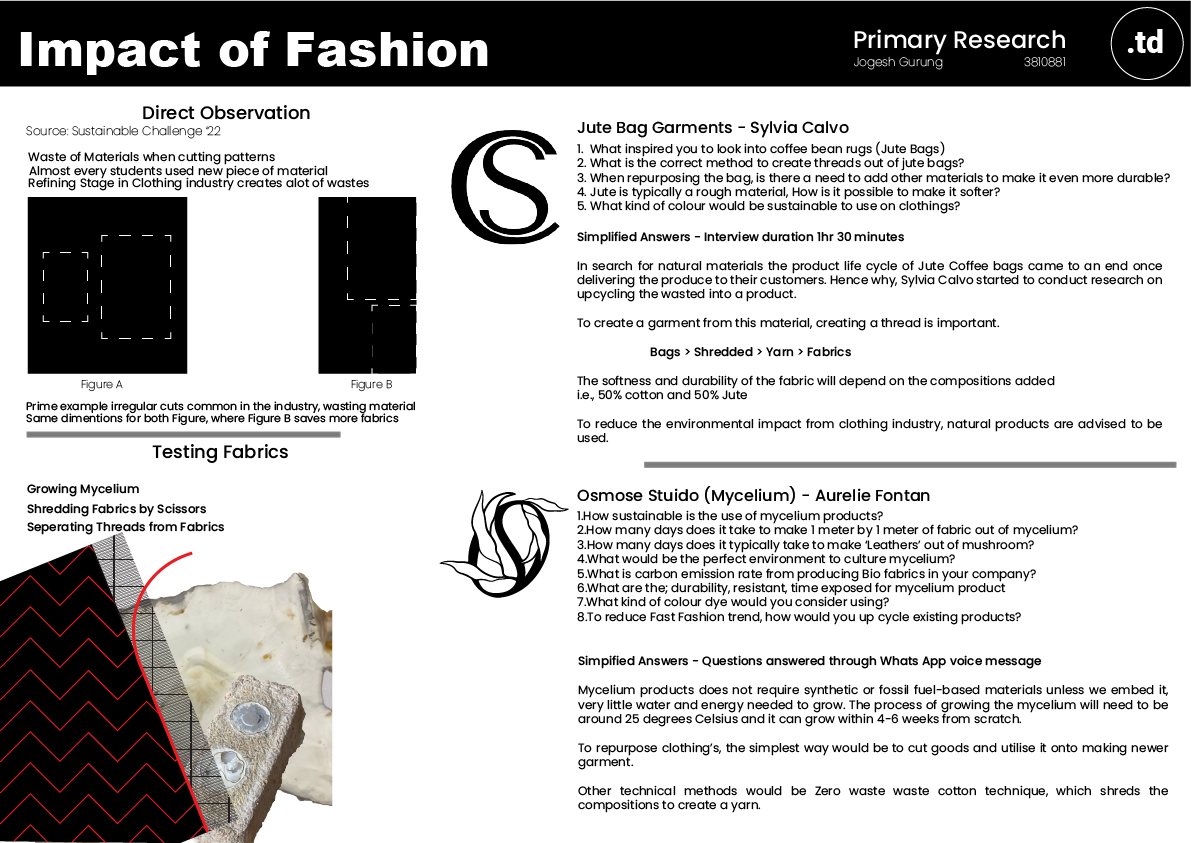

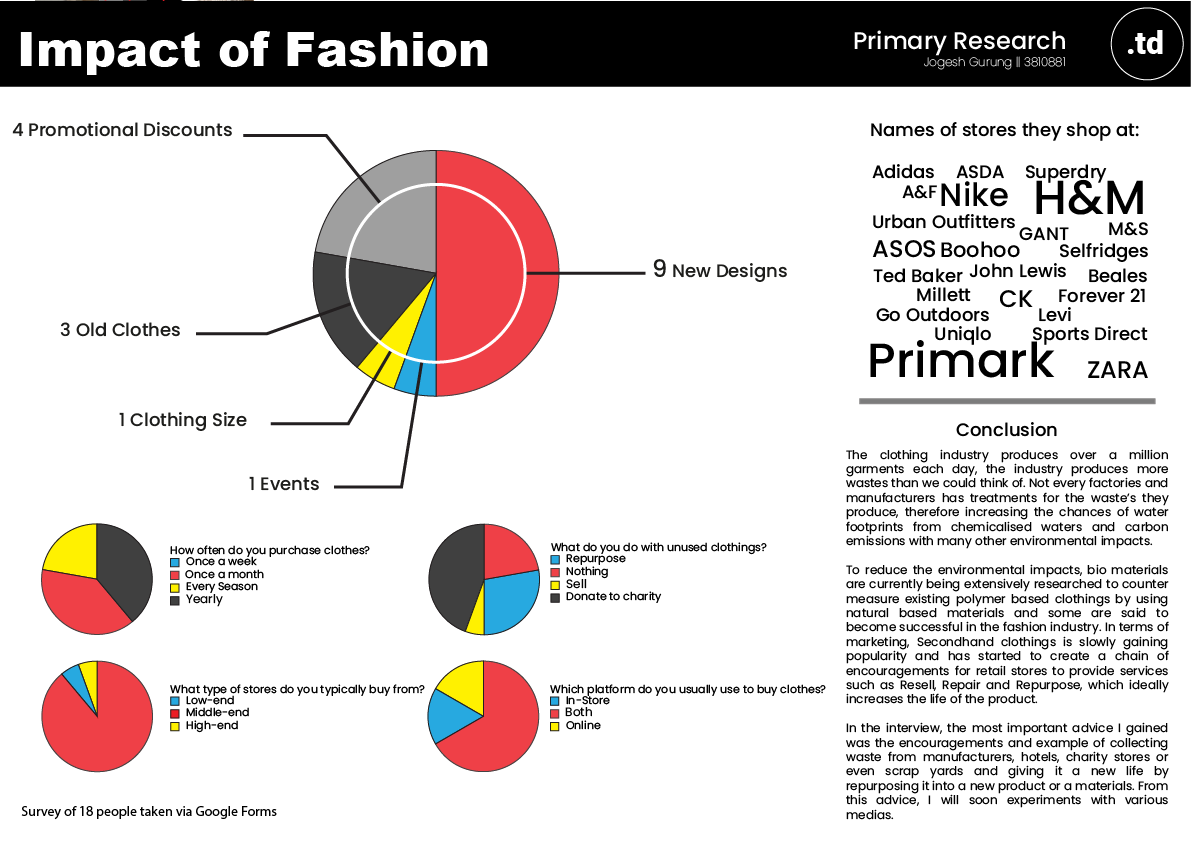

AIM OF THIS PROJECT

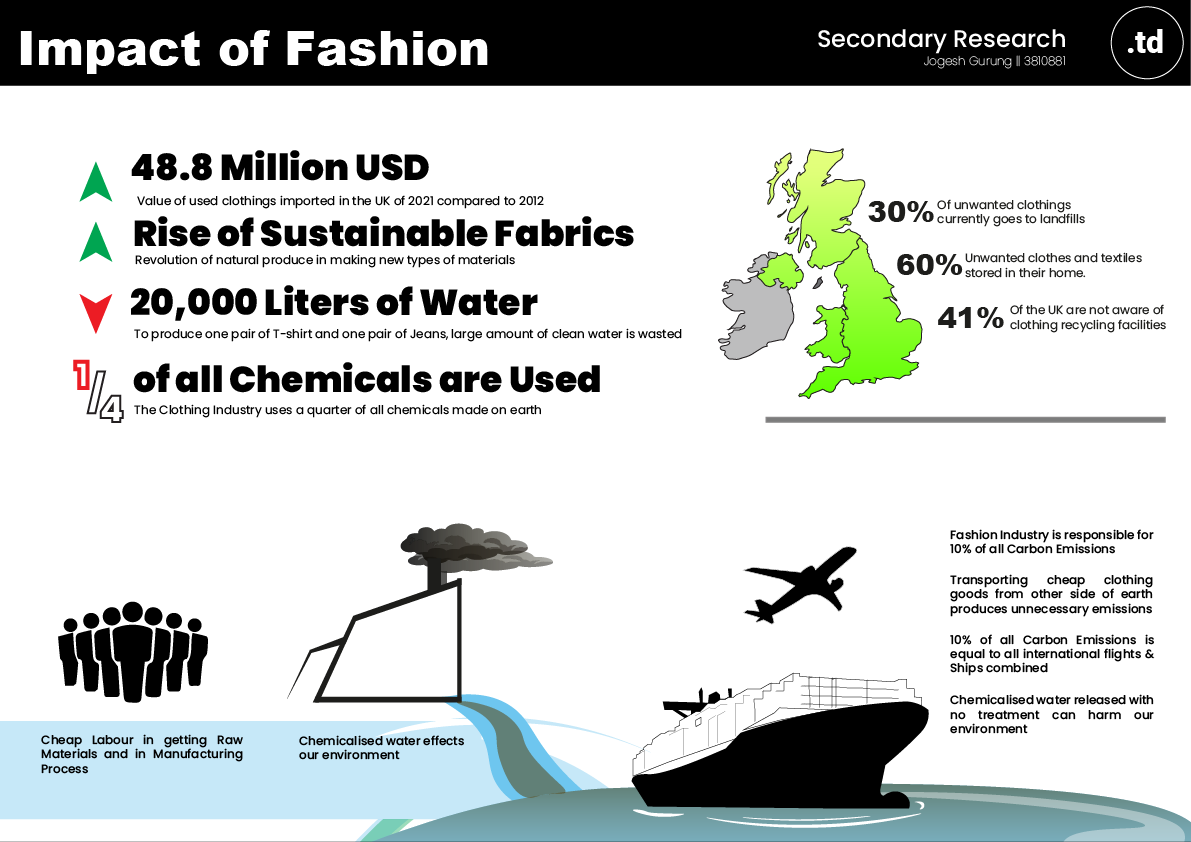

The aim of this project is to reduce the amount of fabric waste that we produce on a daily basis and to find new uses for it in our everyday lives. In this project, I have combined garments and papers to create new products, replacing the need for new materials, whether natural or man-made.

For example, globally, we produce millions of garments every year, yet less than 1% of textiles are recycled (EASC, 2019). This project seeks to address this issue and encourage more sustainable practices.

At first, the company name “Thoughts Decides” had a vulgar pun

associated with it. To avoid this, I chose to brand it as “.td” and

incorporated the theme into my motto. I also wanted this initial

abbreviation of the company to stand out.

associated with it. To avoid this, I chose to brand it as “.td” and

incorporated the theme into my motto. I also wanted this initial

abbreviation of the company to stand out.

The abbreviation “td” now has a concise meaning that aligns with

the ideology of design thinking and represents my brand. After

considering various options, “Thoughts Decides” felt like the

best fit for me. Throughout my design journey, I have struggled

with indecisiveness but have always aimed to make unique and

deliberate choices. This phrase reflects that mindset.

As a fellow young aspiring designer, I understand that many

designers, whether they are beginners or professionals, can

struggle with intrusive thoughts that keep them fixed on their initial

ideas. However, we must strive to think independently and push

ourselves to produce even the most unconventional designs. This

is the mindset that belongs in .td.

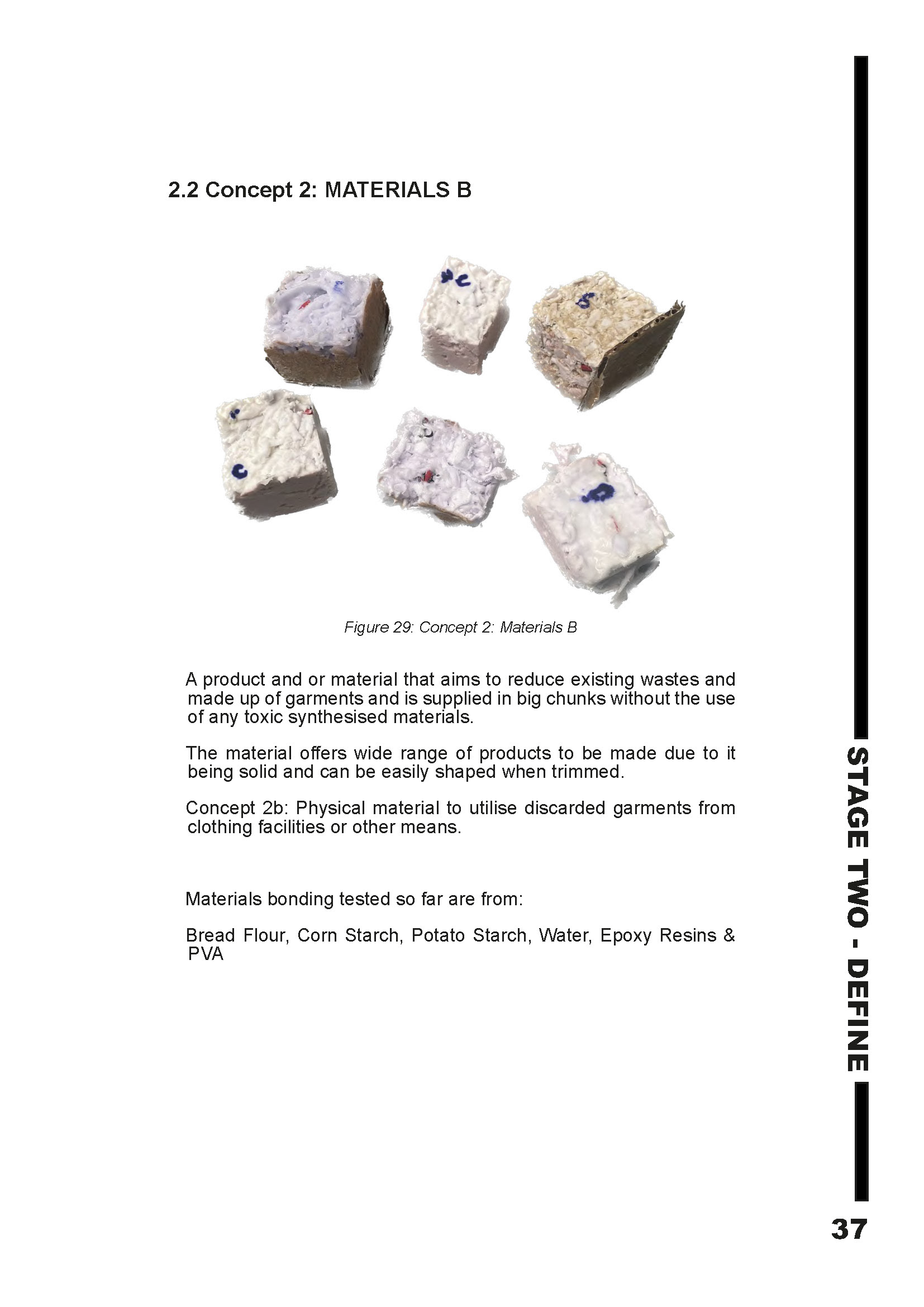

After dissecting general topics into many subsection topics, here are the following topics which I wanted to go fourth for my major project.

Topic: FAST FASHION

Project will now be updated at the end of academic year of 2023

What topic should I focus on within the realm of fast fashion?

- A cost-effective water purification system is needed to address the issue of toxic water waste from local manufacturers in third-world countries. This can help reduce water wastage and promote a healthier environment.

- A solution to tackle the issue of landfill waste by repurposing the waste materials to create a novel material.

- App-based service is designed to assist individuals in upcycling their clothing in an appropriate manner.

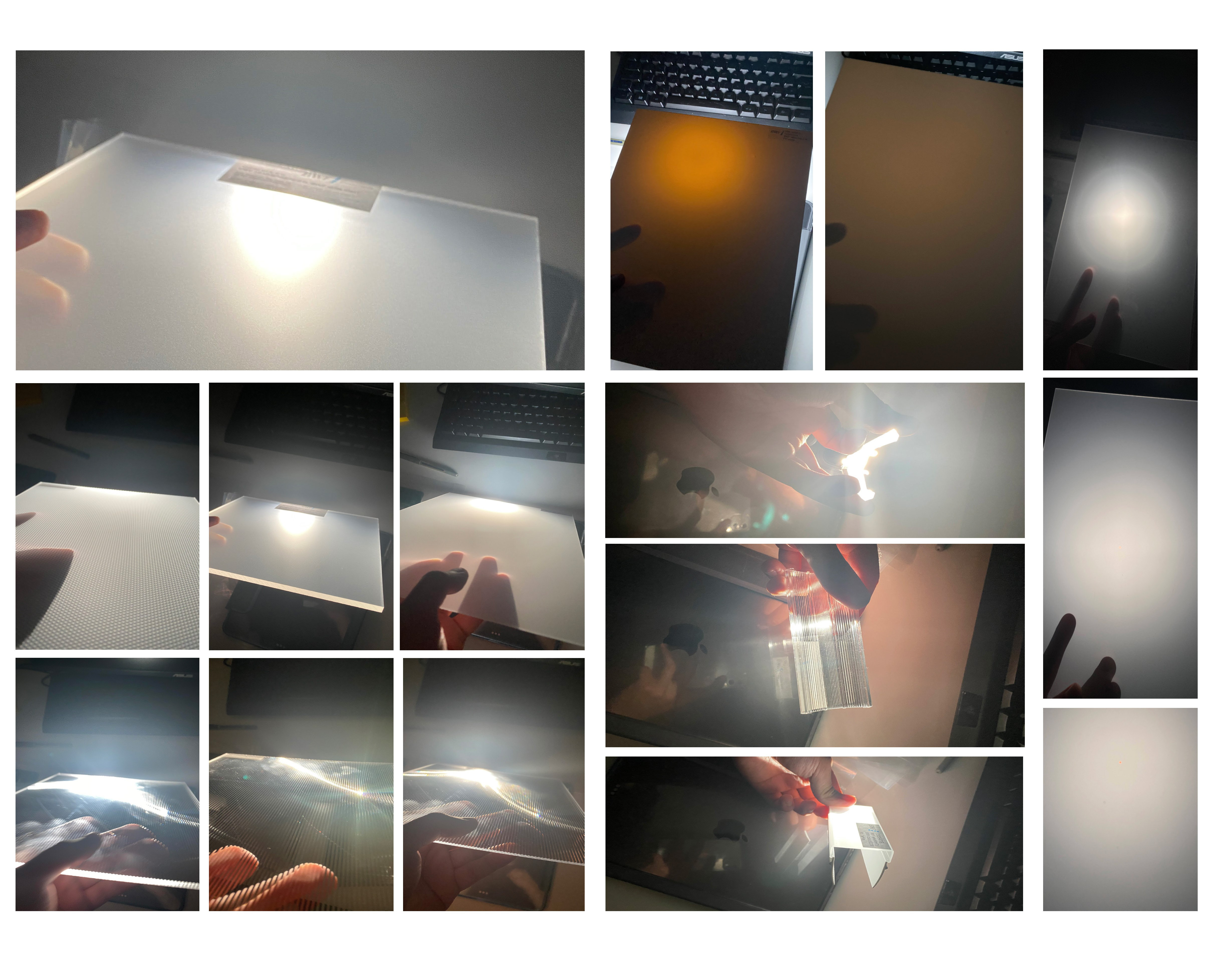

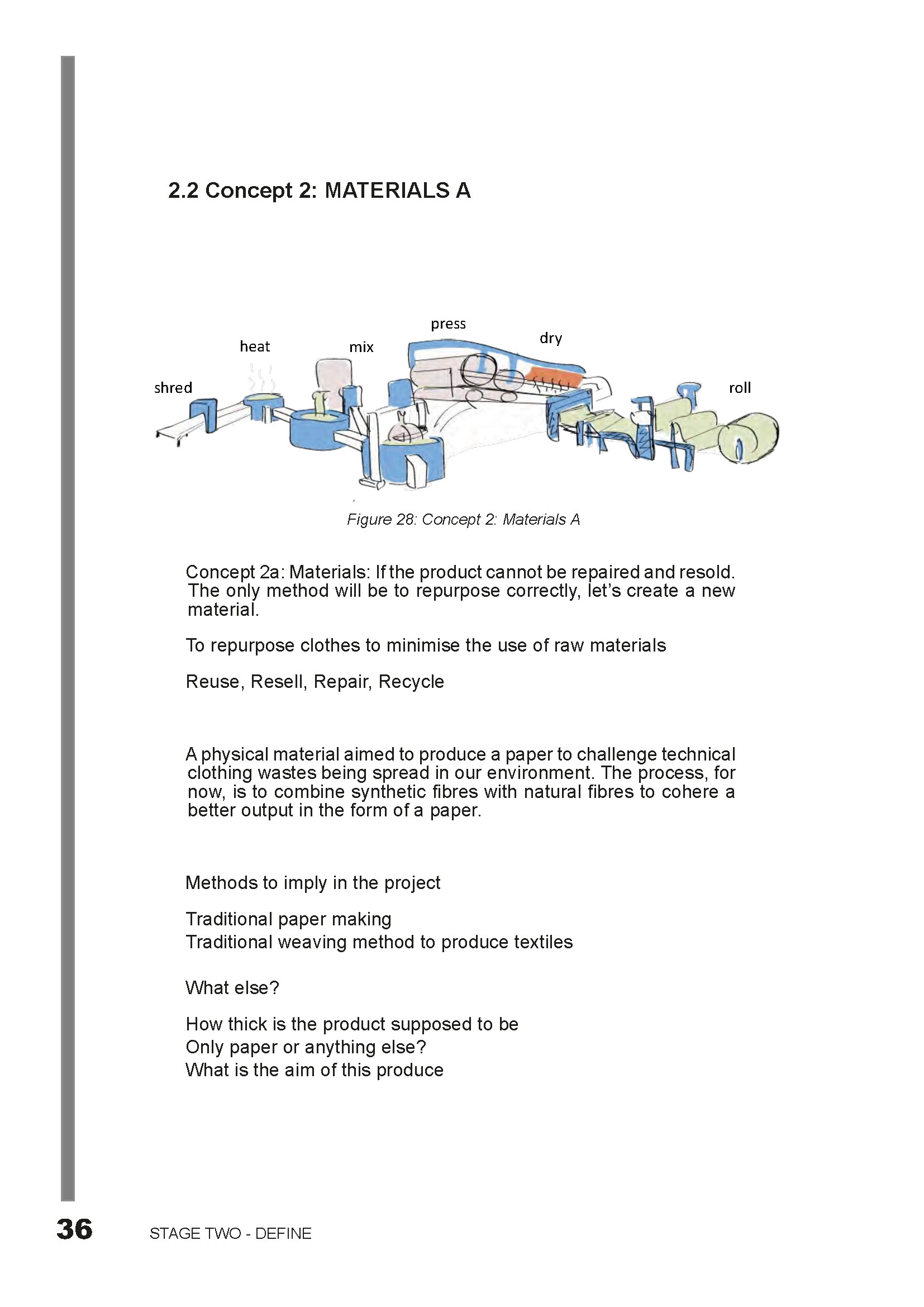

Manufacturing Process of this product

Landscape images of the process FILLING THE WHOLE SHEET.

shredding, processing, moulding, drying, finishing

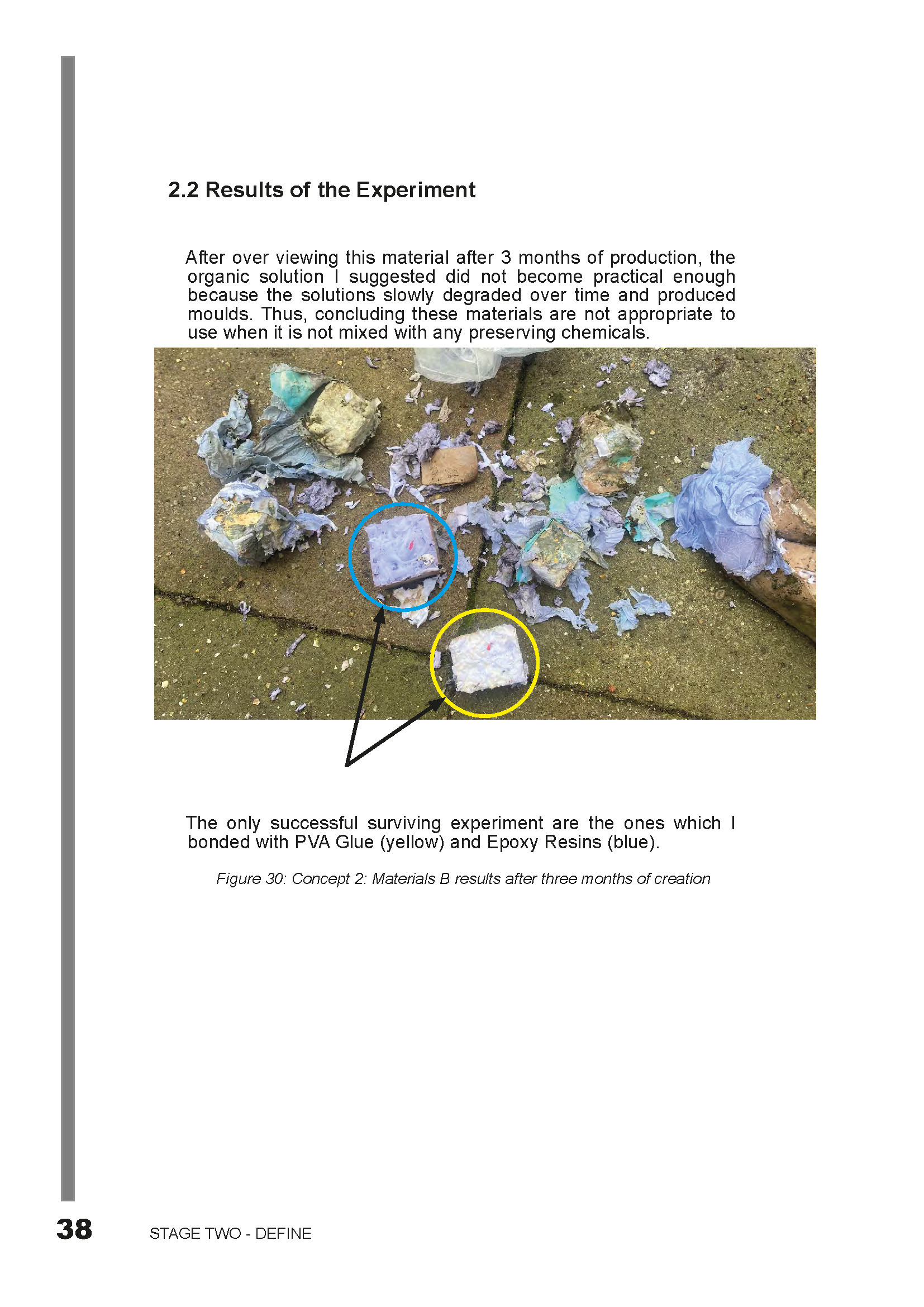

The production of this project involves the use of the traditional paper-making process. To achieve this, the particles of garments have been combined with paper. This decision is based on the presence of cellulose fibres in fabrics that can blend well with paper fibres. A series of tests were conducted using 100% fabrics from various garments, including wool, polyester, and nylon. However, only a few garments demonstrated the desired potential to be produced from a single material. Consequently, the materials were mixed with recycled papers and cardboard, which resulted in positive outcomes. As a result, these two materials were selected as the key components of the project.

some of the results and tests conducted can be seen on the 'Research and Testing' section.

Materials Research and Testings

Experimentation Sections includes experimentation of various fabrics, thickness of papers

and tensile strength report of each tests.

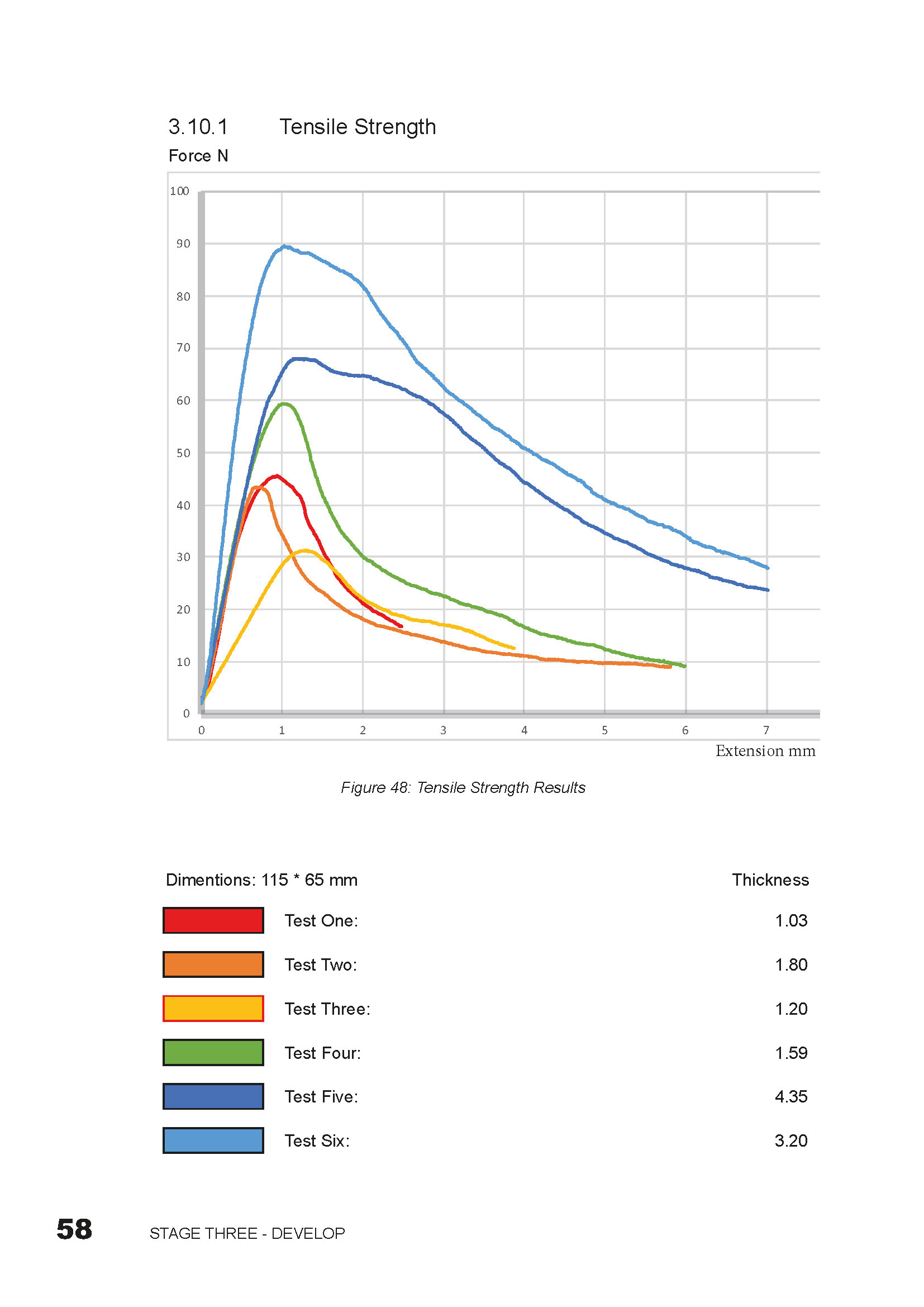

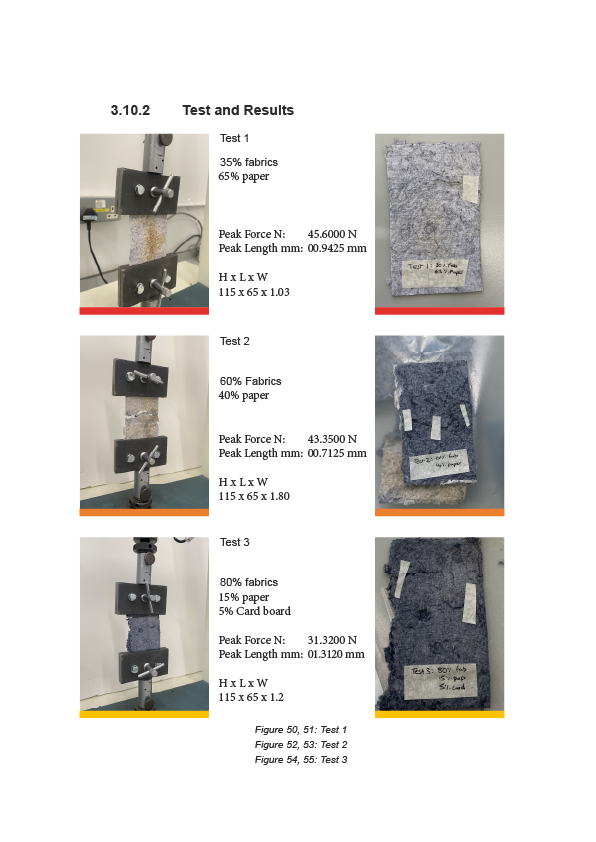

What does the tensile Report suggest of each test?

The term "tensile strength" describes a material's capacity to endure external forces and maintain its form when pulled or stretched to the limit before fracturing. This quality is critical in determining the appropriateness of materials employed in construction, engineering, and manufacturing for particular purposes. As a result, when selecting a material for any project, it is necessary to take into account this essential attribute.

In this project, we analyze the durability of each component based on the rate of different materials used, as well as their size and elasticity. We determine the peak limit of each material by measuring the distance and force applied to it.

External experiments with the material

To make the product fire-retardant, adding a specific solution is recommended. The effectiveness of this solution depends on the amount used and how long it's applied. The fibre particles absorb the solution, but its effects are temporary. A disadvantage of this solvent is that higher concentrations cause more crystal particles to be visible.

It's important to note that exposure to high levels of this material can result in skin irritation, redness, and dryness. As such, caution should be exercised when developing this material further to improve its efficacy. However, using low doses of this solvent poses no harm to users.

Images of Samples when tested with fire

Before : After

Upon the complete drying of the solution on the material, the extent of burn damage when exposed to fire is significantly reduced.

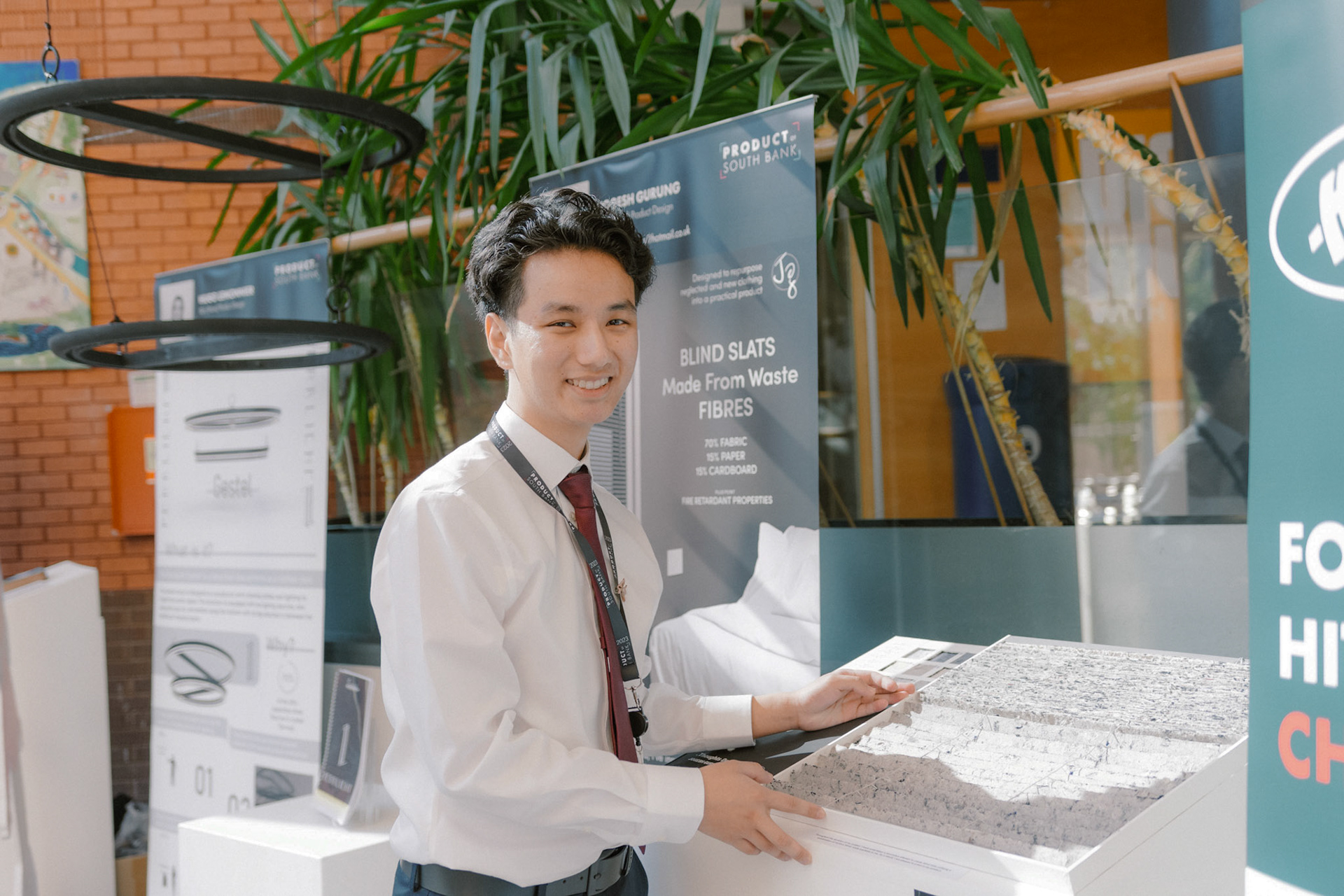

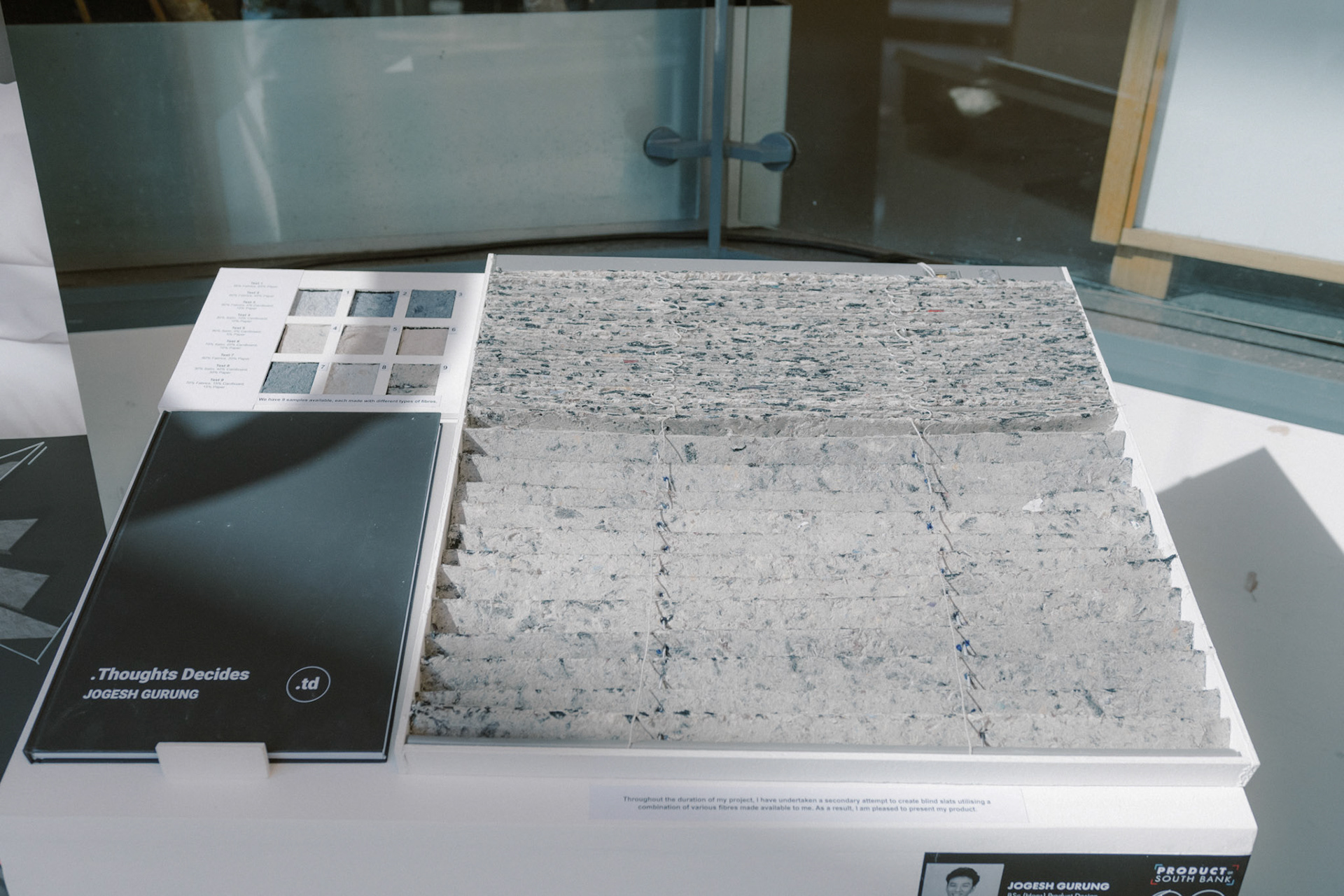

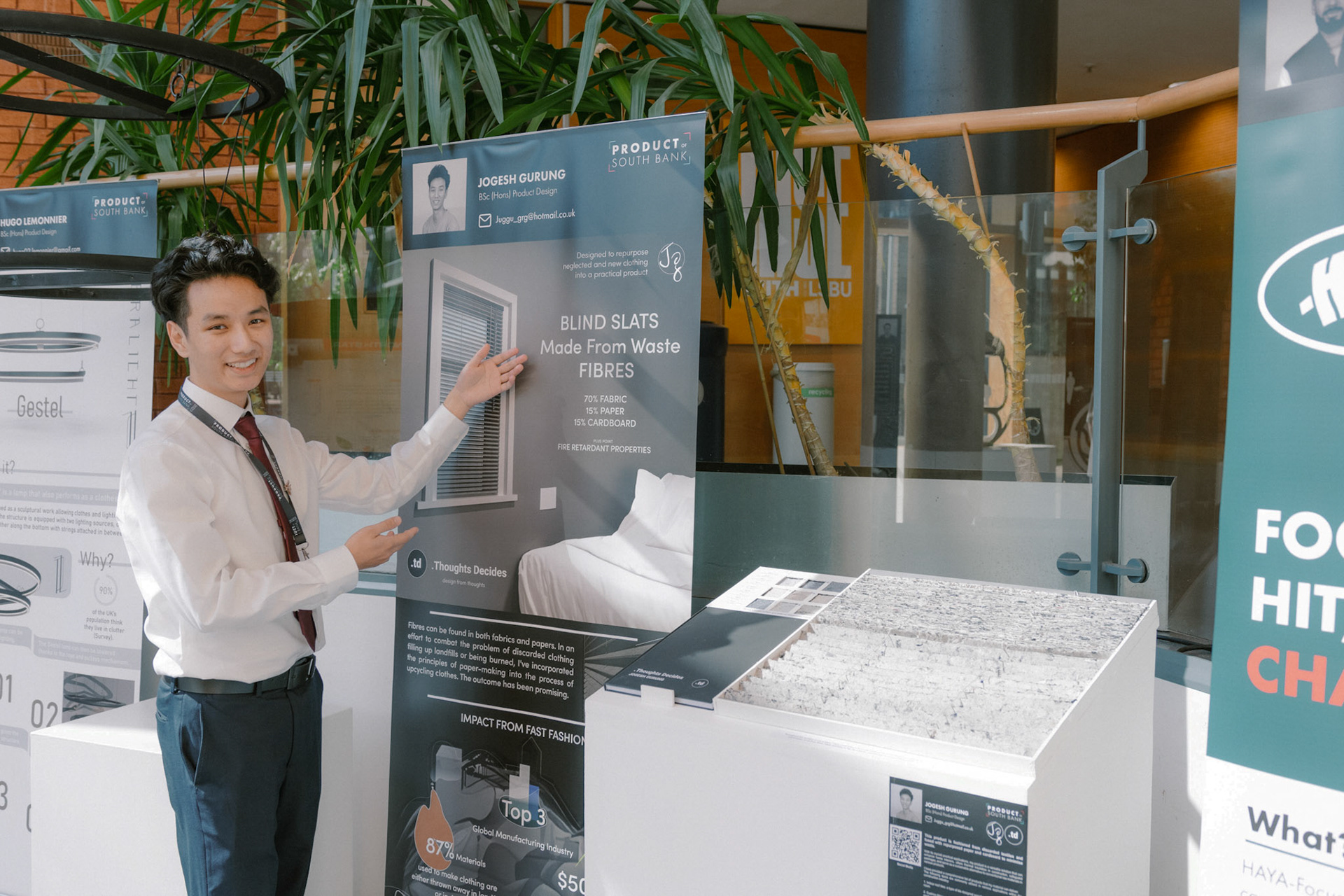

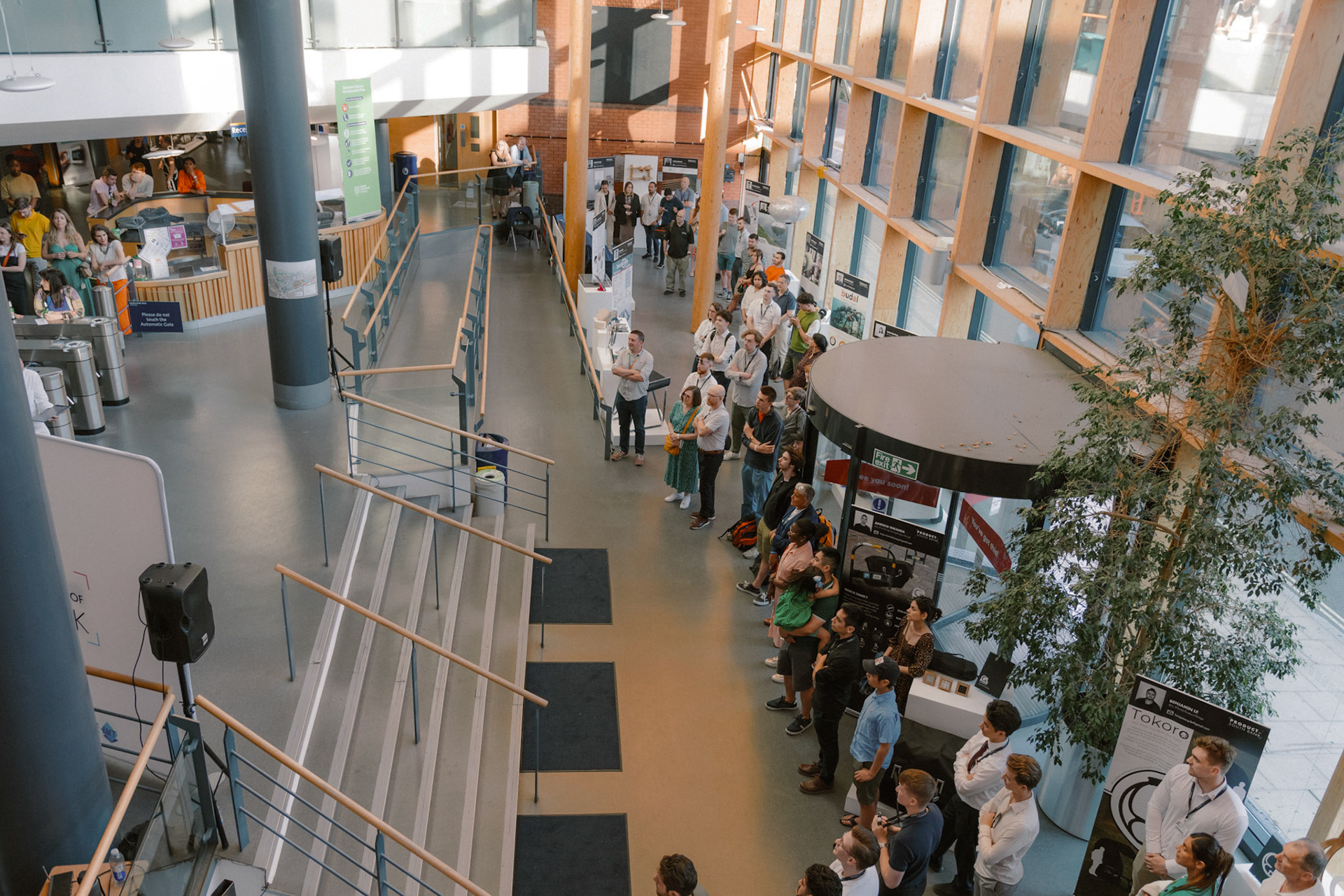

Exhibit at London South Bank Univ. - 14-16 June 2023

As part of my major project, I conducted a reverse engineering project on a functional blind. My objective was to adjust the blind slats using a composite material of paper, cardboard, fabrics, and water. The process involved careful analysis of the existing blind and the creation of a new composite material that would provide suitable characteristics for the task at hand.

The resulting composite material was then used to adjust the blind slats, resulting in a functional and aesthetically pleasing final product. This composite material demonstrates the possibility of creating functional and environmentally friendly products by leveraging commonly available materials.

Overall, the project highlights the value of reverse engineering as a tool for understanding and improving upon existing products. It also demonstrates the potential for sustainable design practices by using environmentally friendly materials.

With the support of my research and development, I have successfully addressed seven of the United Nations Development Programme's (UNDP) sustainable development goals. My primary objective is to create a positive impact on the garment industry by implementing innovative ideas, overcoming associated challenges, and transforming them into reality.

Digital overview in render format

Potential of this material

The material under consideration exhibits vast potential and can be utilised with the molded fiber concept, which would expand its scope of application to include packaging, decoration, and other related areas in the near future. Analogously, garments, like paper, possess the capacity to generate a multitude of artifacts. If the two could be combined industrially, the possibilities for innovation and creativity would be limitless.